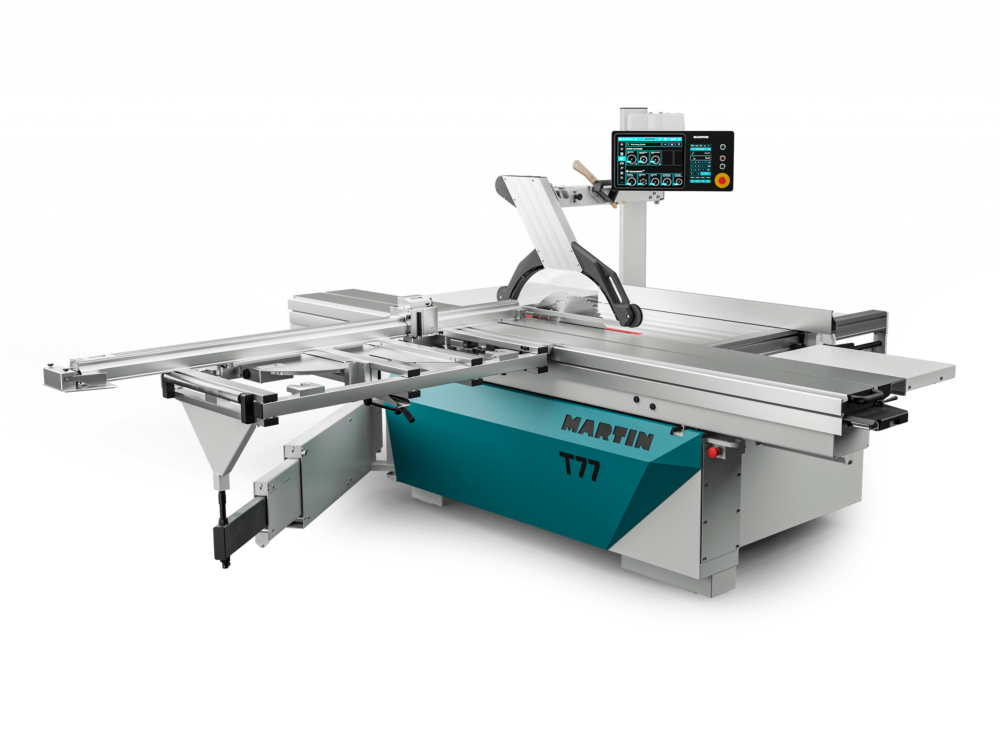

Precision is what MARTIN means to me

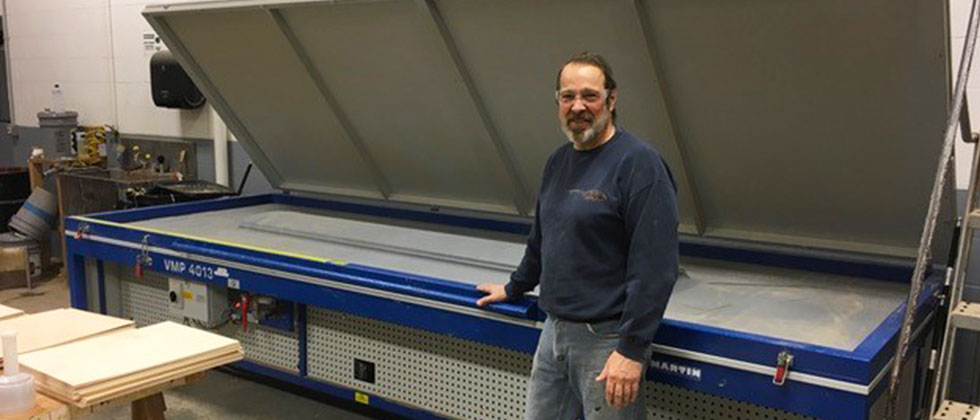

„My primary product is custom cabinetry for residential projects. Having a versatile saw that can cut a perfect miter on a 10’ panel then in seconds be used for ripping solid wood allows unlimited creativity. Offering a complete product line from cabinetry to solid wood countertops to large windows and doors the MARTIN machinery lets me offer our clients what they want. With the T54 Jointer I can comfortably mill up stock for 10’ doors, knowing that it will be flat. Precision is what MARTIN means to me.“

Scott Slater

Bespoken Woodworks

Sierra Madre, CA