Greatly simplified our working processes

„We are using the BARTH MULTI Press now. We were on the lookout for such a device for a long time and are now very happy that we have this press. This has greatly simplified our working processes. A single worker can glue carcasses, drawers, table boards and a lot more. Otherwise two workers are always needed when working with traditional clamps. Everything which we produce in our workshop is glued in this press.“

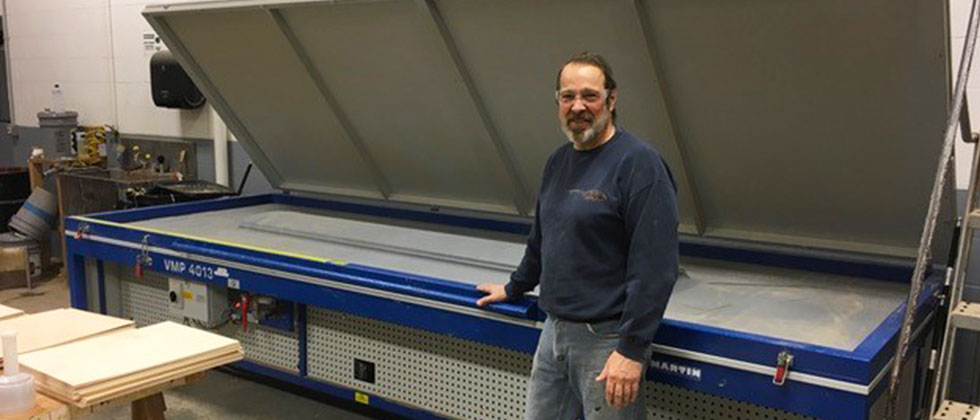

Roland Oberlader

Roland’s Joinery

Telkwa, British Columbia