Paying for itself

„The machine is a huge time saver. We are averaging about 10 hours per job faster with this machine, so the GANNOMAT ProTec is really paying for itself.“

Neal Walden

Walden & Co

Healdsburg, CA

Short introduction:

• Small footprint requirement, less than 3,3 m2

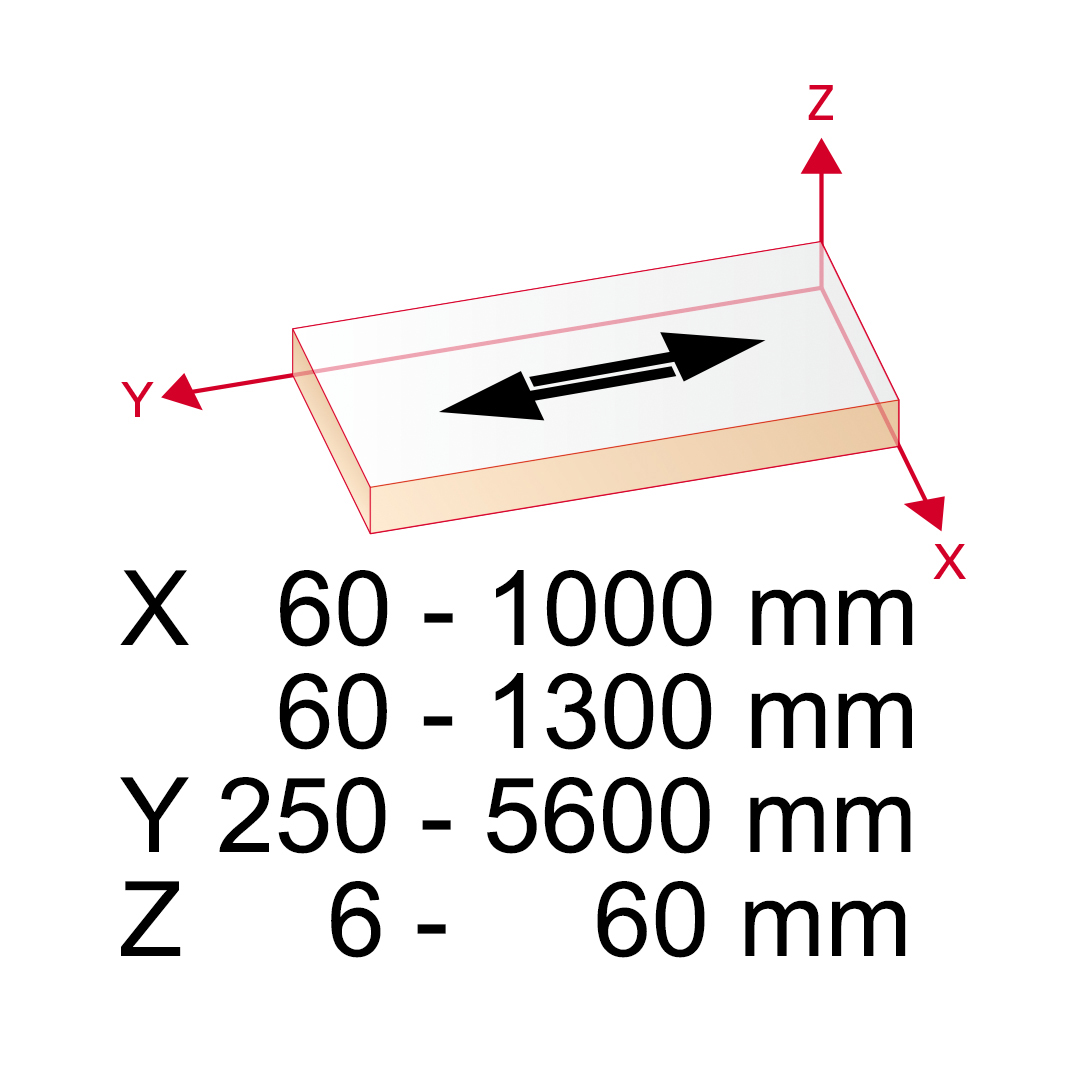

• Large (1000 x 5600 x 60 mm) and small (60 x 250 x 6 mm) workpiece dimensions

• Gentle workpiece handling by air jets

• Precision through double laser measurement and workpiece straightening

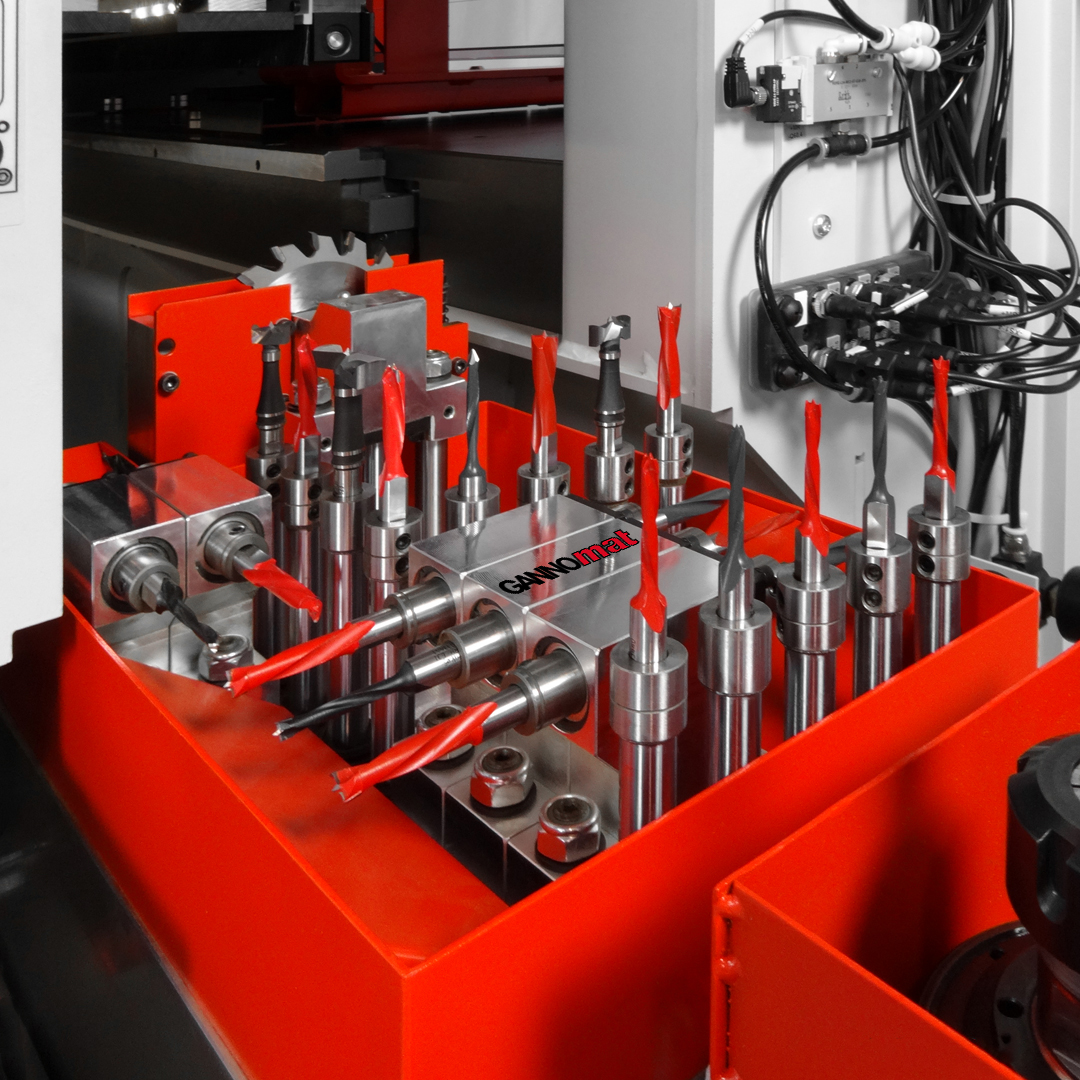

• Fast processing through 21/23 drilling spindles

• 21/23 drilling spindles for zero setting times

• Stable grooving unit till 8,3 mm saw blade width

• Strong routing unit 5,5 kW (S1), option

• Automatic tool changer for routing unit, option

New Options

• Working width 1300 mm (instead of standard 1000 mm)

• Lamello P-System package for routing of Lamello P-System pockets for Clamex, Clamex Flexus, Tenso, Bisco, Divario

• Lamello Cabineo drilling/routing

Workpiece dimensions for the daily practice.

Automatic workpiece transport by gripper and at machine table with air-jet system.

The GANNOMAT ProTec is equipped for practical cabinet production:

• Vertical & Horizontal CNC drill block

• Drilling process on 5 sides

• Grooving process

• No set up

• Traditional processing from underneath

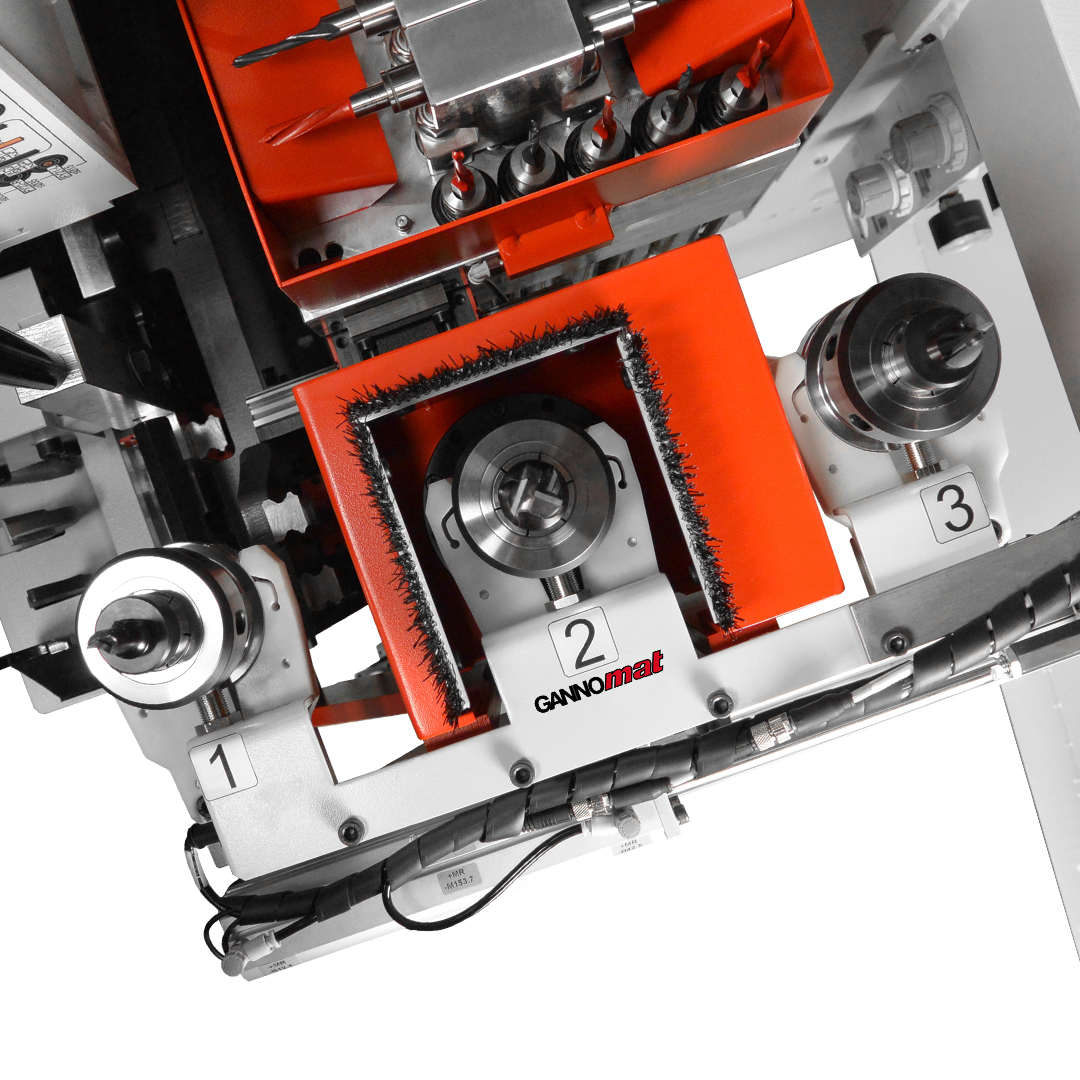

Automatic tool changer for routing unit with 3-fold magazine for HSK63F tool holders (option).

The optional automatic tool changer can be equpipped with tools for routing of Lamello P-System pockets for Clamex, Clamex Flexus, Tenso, Bisco, Divario.

Testimonials

Paying for itself

„The machine is a huge time saver. We are averaging about 10 hours per job faster with this machine, so the GANNOMAT ProTec is really paying for itself.“

Neal Walden

Walden & Co

Healdsburg, CA

Fast, very accurate and operator friendly

„We bought a WEBER wide belt sander from MARTIN Woodworking Machines in 2017 and were very satisfied with this machine. When we had to increase our efficiency in the field of cabinet making, we contacted MARTIN again and found the perfect solution with the GANNOMAT ProTec. The ProTec works fast, very accurately and is very operator friendly.“

Marek Weglicki

Best Mark National

Irvington, NY

Impressed by the user-friendliness

We have opted for the ProTec because it offers the best possible machine package. The machine convinces with its precision (flush corner connections), speed, footprint and price. We have been using the machine for several weeks and are impressed by the user-friendliness of the software.

Doug Sinjem

D.L. Sinjem Co. Inc.

La Habra, CA

A demonstration convinced us

We are producing high-quality furniture and interior fittings and wanted to minimize our production time without compromising quality. A demonstration convinced us of the GANNOMAT ProTec machining center. The ProTec won us over by its powerful technology and high level of precision of the manufactured parts.

Lance Mack

Mack Custom Woodworking

Shokan, NY

Don’t hesitate to contact us!