Great resale value

„I am building high end custom furniture and for this I needed the right machines for precise and quick results. I chose the Weber wide belt sander because it gives me the best flexibility for solid wood, veneer and lacquer/sealer sanding. With the patented WEBER CBF system, I get almost no oscillation and the few marks left are removed by the patented Weber planetary brush head aggregate. The planetary head not only takes the marks away it also can sand deep into profiles and breaks the edges so that we do not need to sand by hand anymore.

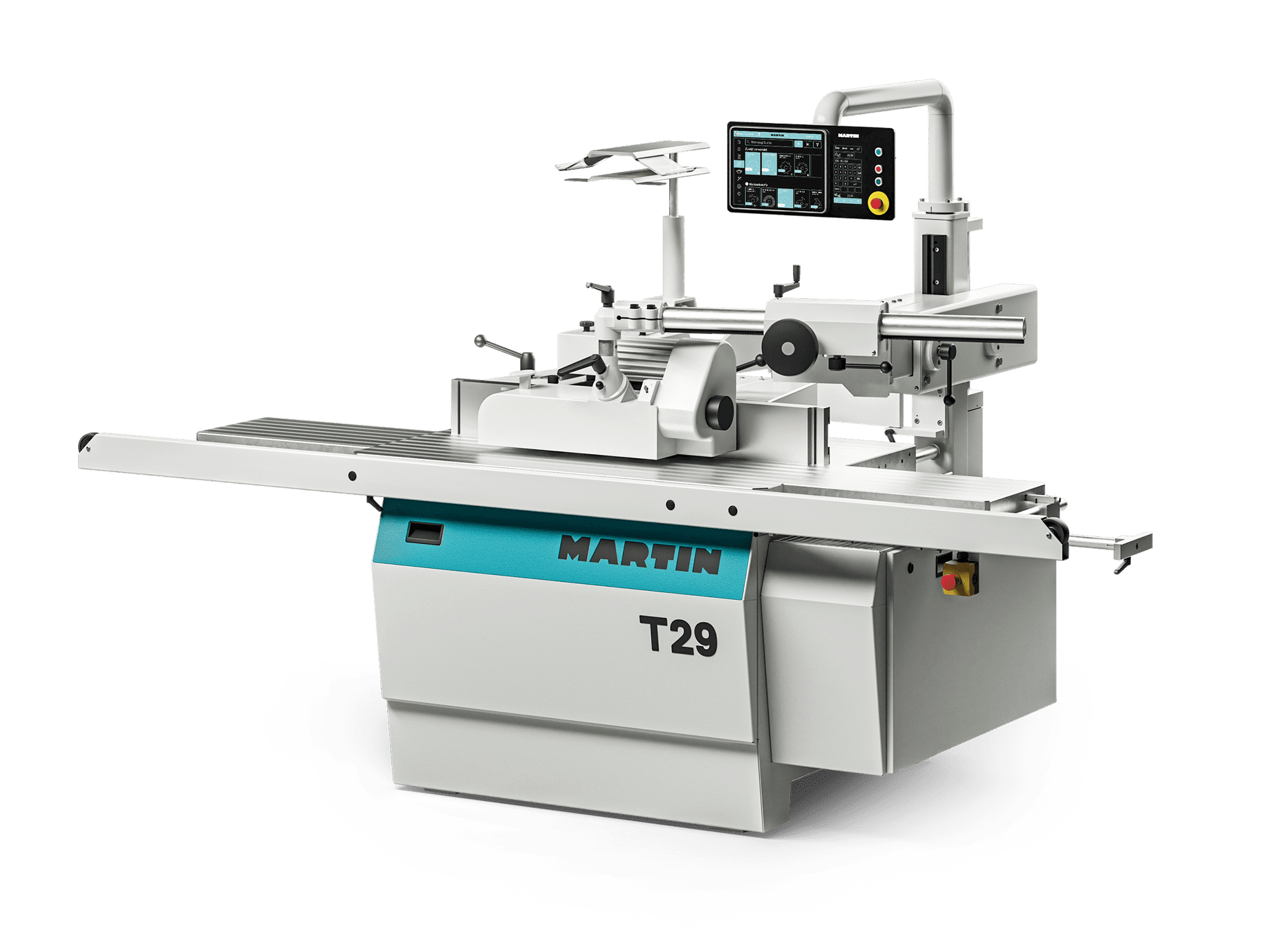

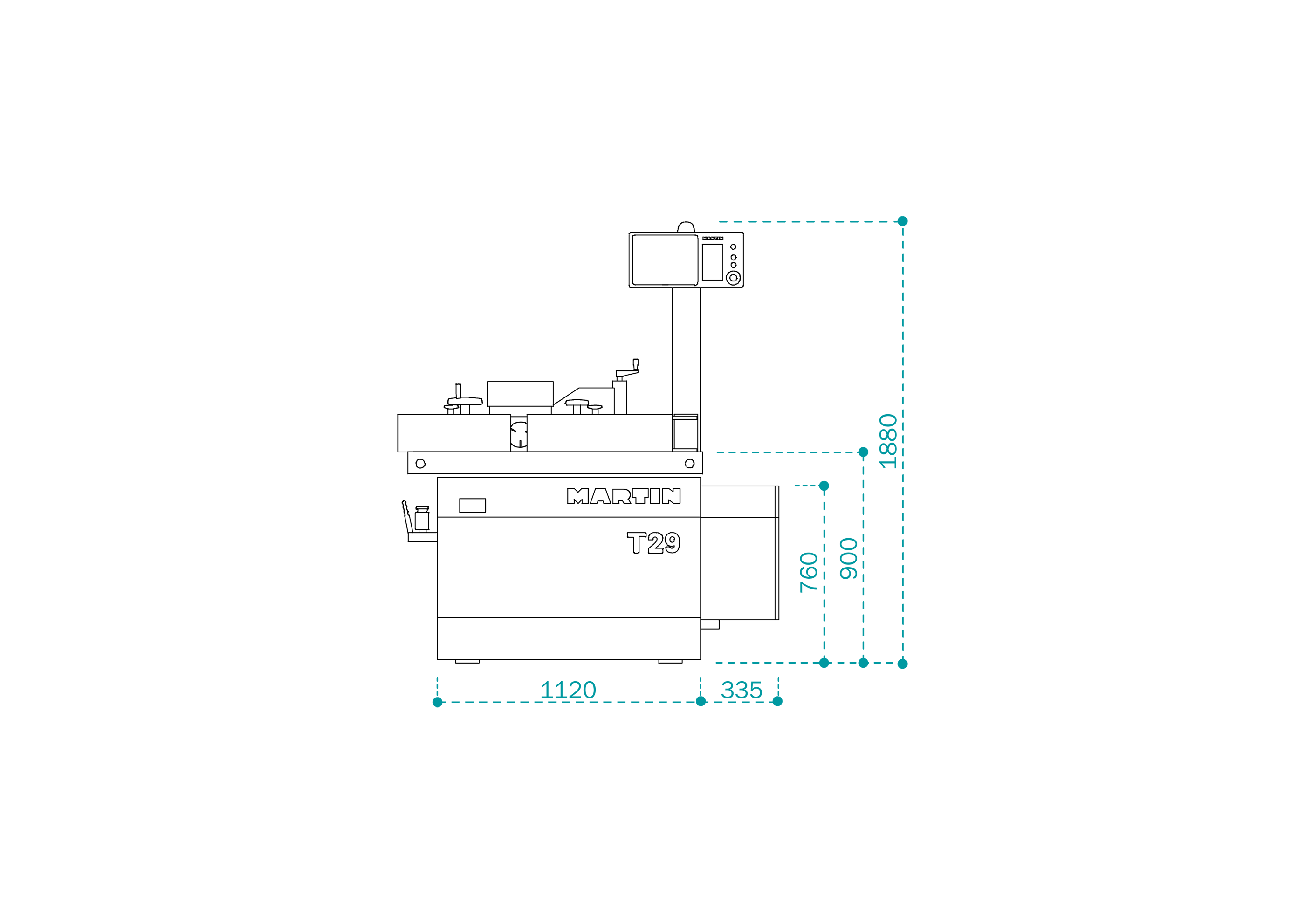

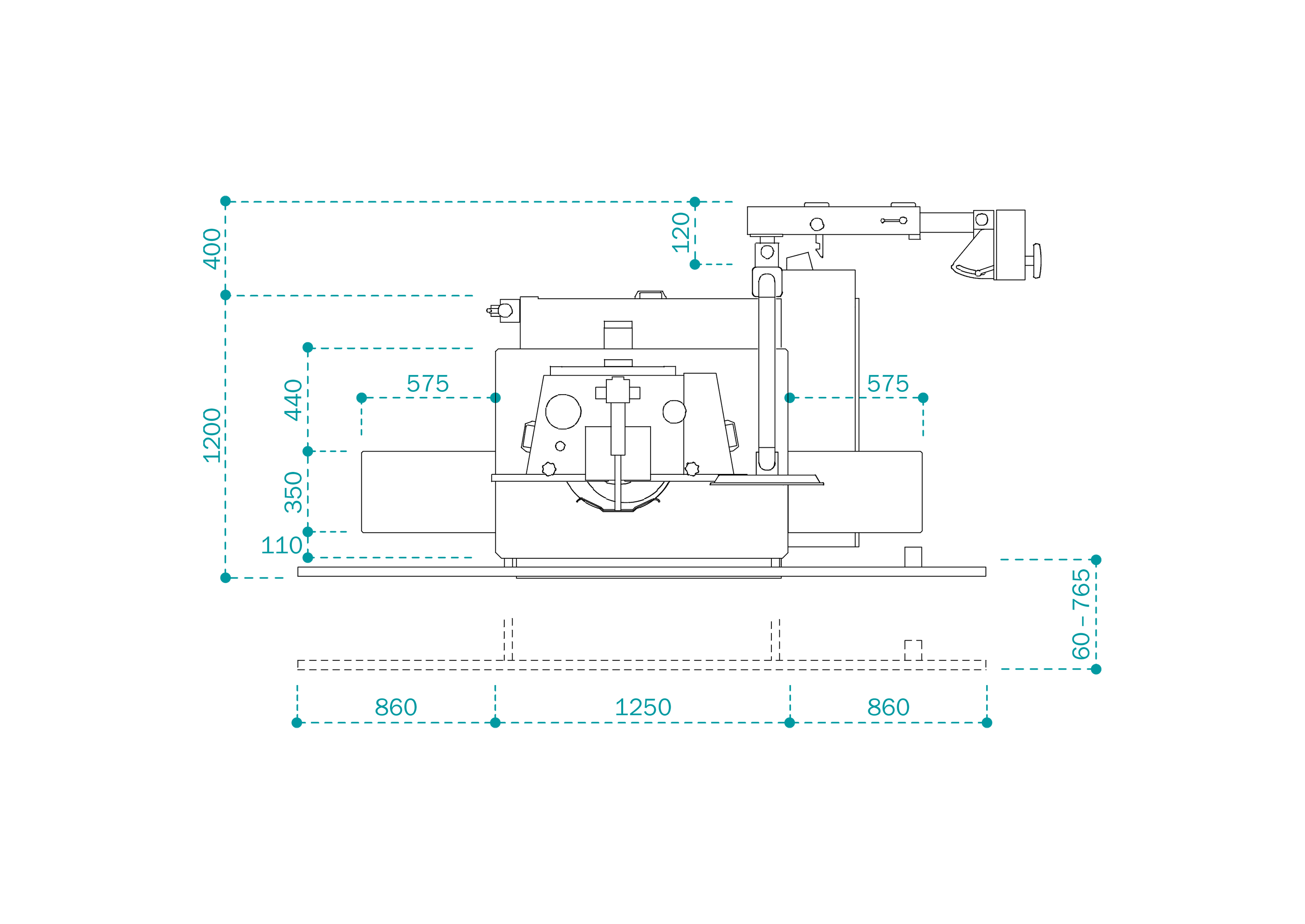

I also purchased a tilting arbor MARTIN T27 Flex shaper, T45 thickness planer, T54 jointer and the T75 Prex dual-tilting sliding table saw. These machines are heavy duty and carry with them a great resale value…something that you do not see much anymore with industrial woodworking machinery.“

Isaac B. Hayun

Trieste Corp.

Long Island City, NY